Kegerator Repair Tips and Benefits

Regular maintenance can prevent many common issues and extend the lifespan of the unit.

Addressing issues at the first sign of trouble minimizes repair costs and downtime.

Repairs during off-peak seasons can ensure optimal performance during busy times.

Ways to make Kegerator Repairs work in tight or awkward layouts.

Popular materials for Kegerator Repairs and why they hold up over time.

Simple add-ons that improve Kegerator Repairs without blowing the budget.

High-end options that actually feel worth it for Kegerator Repairs.

Finishes and colors that play nicely with Kegerator Repairs.

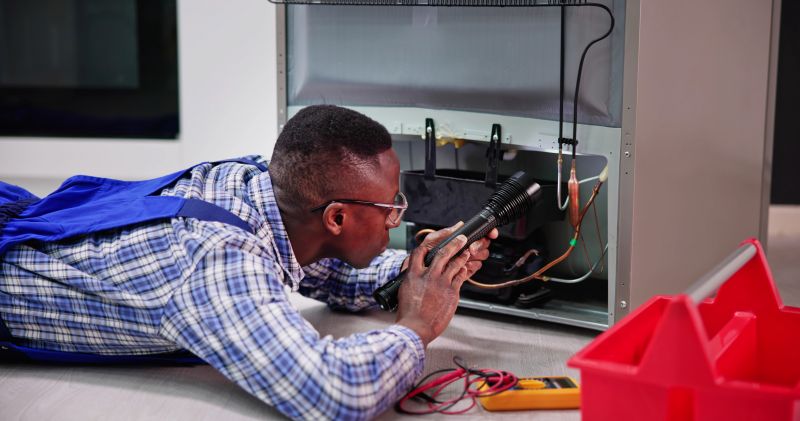

Kegerator repairs are most effectively performed when issues are identified early. Regular inspections can reveal signs such as inconsistent cooling, leaks, or strange noises. Addressing these problems promptly helps prevent more extensive damage and maintains optimal operation. Statistics indicate that early repairs can reduce costs by up to 30% and extend appliance lifespan by several years.

The best time for repairs often aligns with periods of low usage, such as late fall or winter, when demand is reduced. This timing allows for repairs to be completed without disrupting service during peak times. Additionally, scheduling repairs before major events or busy seasons ensures the kegerator is fully functional when needed most.

Troubleshooting refrigerant levels and compressor function can resolve temperature problems.

Sealing or replacing faulty hoses and fittings restores proper pressure and prevents waste.

Worn-out parts like thermostats or valves should be replaced during scheduled repairs.

Regular cleaning of coils and seals improves efficiency and prevents breakdowns.

Little measurements that prevent headaches on Kegerator Repairs day.

A 60-second routine that keeps Kegerator Repairs looking new.

A frequent mistake in Kegerator Repairs and how to dodge it.

Small tweaks to make Kegerator Repairs safer and easier to use.

| Optimal Repair Timing | Reason |

|---|---|

| Off-peak seasons | Less disruption and easier scheduling |

| Before major events | Ensures functionality during high-demand periods |

| When issues are first noticed | Prevents escalation of problems |

| Scheduled maintenance intervals | Maintains consistent performance |

| After heavy usage periods | Addresses wear and tear promptly |

Performing repairs at the appropriate times can significantly improve the reliability and efficiency of a kegerator. Regularly scheduled maintenance and early intervention help avoid costly emergency repairs. Proper timing also ensures minimal downtime, allowing for continuous service during peak times.

Scheduling repairs during periods of low demand minimizes service disruptions.

Ensuring the kegerator is in top condition before large gatherings.

Timely repairs prevent minor issues from becoming major failures.

Aligning repairs with seasonal slow periods for convenience.

Lower-waste or water-saving choices for Kegerator Repairs.

The short, realistic tool list for quality Kegerator Repairs.

Rough timing from prep to clean-up for Kegerator Repairs.

Quick checks and paperwork to keep after Kegerator Repairs.

Timely repairs contribute to consistent beverage quality and operational efficiency. Regular inspections and addressing issues early can lead to cost savings and prolonged equipment lifespan. Users are encouraged to contact for scheduling repairs during optimal times to ensure reliability.

Examples that show the impact a good Kegerator Repairs can make.

Ways to make Kegerator Repairs work in tight or awkward layouts.

Ways to make Kegerator Repairs work in tight or awkward layouts.